|

Product Description

HJ107(151)(NO Manganese-oxide flux)

Line with GB/T17854-1999

F308-H0Cr2lNil0

F308L-H00Cr2Ni10

DESCRIPTION:

HJ107(151)is a fused type no manganese-oxide flux with pumiceous granule of bluish gray to dark gray color, about 10-60 mesh in size. This flux is designed for welding of auste-nitic stainless steel and is of characteristics with less carbon increment and less chromium loss.

APPLICATIONS:

This flux is recommended to use with H0Cr21Ni10, H0Cr21Ni10Ti, H0Cr24Ni12Nb, , H00Cr21Ni10Nb\H00Cr26Ni12\H00Cr21Ni10 wires and strips doe welding of stainless steel and anti-corrosion cladding of nuclear pressure vessels and petrol chemical installations. It is also used for repair welding of high welding of high manganese steel with H0Cr16Mn16 wire.

For welding of niobium stabilized stainless steel, the flux of LH. HJ107Nb may be selected to solve the problem of difficult removal of welding slag.

TYPICAL PROPERTIES OF CLADDING LAYERS:

Being matched with H00Cr26Ni12(first layer) and H00Cr21Ni10(surface layers)welding strips for cladding on 50mm thick ISMnMoNb steel.

1. Carbon increment≤ 0.01% Chromium loss≤ 1.5%

2. After sensitization treatment, the specimen has passed the intercrystalline corrosion test in accordance with GB4334.5-1990< Method of corrosion test by sulfuric acidc-opper sulfate for stainless steel>

GUIDELINES FOR USAGE:

1. Dry the flux at 250 for 2 hours before use.

2. Completely remove rust, oil and dirt from the groove surface prior to welding.

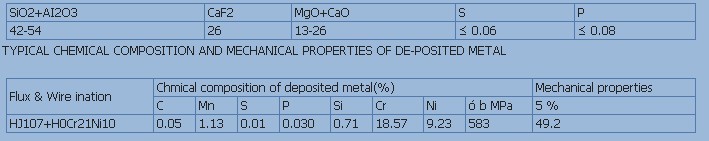

TYPICAL FLUX COMPOSITION RANGE(%):

|